Back before Noah came over on the Mayflower, fountain pens didn’t have fillers. You unscrewed part of the pen, took out an eyedropper, and fed the pen like a week-old kitten. Clumsy. Potentially messy. And, if you happened to run out of ink in the wrong place, embarrassing as all get out. What to do, what do to?

Wouldn’t it be great to be able to carry some extra ink! That’s what Claes Boman must have thought one day back in about 1889. The unusual thing is that he did something about it. In January 1890, he applied for a patent on his fountain pen and the removable glass ”supply-vials” in which its ink supply was kept. By the end of April, Boman had in his hands U.S. Patent Nº 426,758 for the first cartridge fountain pen, and the pen looked like this:

The heart of this pen is a rubber plug. Its front end butts up against the back end of the feed, and its back end is a nipple that fits inside the mouth of a glass cartridge that is nothing more than a length of glass tube with one end closed off square. Some form of seal kept the ink inside, and the user would remove that seal and fit the cartridge onto the nipple, exercising due care to avoid spillage. All in all, it was better than the eyedropper method. And it eventually led to where we are today.

The point of this exercise is that one day not too long ago, one of these pens reached my workbench. It was, of course, not working. The plug was about as pliable as a chunk of good old New Hampshire granite. Here’s what it took to restore this baby.

The first task was to disassemble it. The first part was easy:

Now to get the nib and feed out of the section. This was not as easily done as said, especially since the plug was broken off right at the end of the section. But after I chiseled the hardened plug out, here’s what I had:

That nib, by the way, is brass. The feed is really primitive, lacking true capillary fissures, but it apparently worked once, so it should work again. Let’s make a new plug. The color of the original plug suggested that it was probably ordinary white gum rubber, so I grabbed a rubber stopper and cut it to pieces.

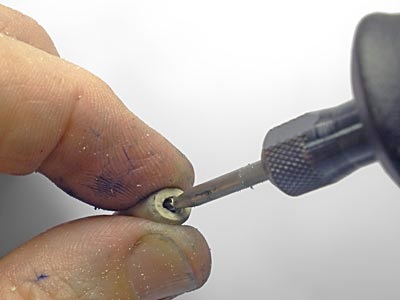

Next, I applied the square piece of rubber to a rotary tool’s grinding drum to make it round.

Then a little more grinding created the cartridge nipple:

Changing the drum for a bur, I attacked the inside to make the bore. I worked from the back to start, then I removed the plug and finished from the front end, which mates to the feed.

Clean up the nib and feed, put it all together, and here’s what we get:

The amazing thing is that when I filled it up, it really did work. The client was overjoyed.

Y’know, there’s always what the late Paul Harvey called the r-r-r-r-r-r-r-r-rest of the story. The rest of this story is that Boman worked for the Eagle Pencil Company. They put the pen into production, not only in the Basic Black version shown above, but also in fancier dress. Like this:

Who said cartridge pens are boring?